Views: 0 Author: Site Editor Publish Time: 2025-07-09 Origin: Site

You use a paper bag almost every day, but have you ever wondered where it comes from? A paper bag starts its journey as wood pulp, mainly from sustainably managed forests. People first invented the paper bag in the 19th century, and since then, it has changed from simple designs to the sturdy grocery bags you see today. In 2023, Europe produced 74.3 million tonnes of paper, while North America consumed 2.7 million tons of brown and kraft papers. This shows just how important the paper bag is around the world.

| Region / Country | Statistic Description | Numerical Value | Year |

|---|---|---|---|

| Europe | Paper production volume | 74.3 million tonnes | 2023 |

| North America | Consumption of brown and kraft papers | 2.7 million tons | 2023 |

Paper bags start as wood pulp from sustainably managed forests or recycled materials, helping protect the environment.

Important inventors like Francis Wolle and Margaret Knight improved paper bag designs, making them stronger and easier to use.

Kraft paper, made from softwood trees, gives paper bags their strength and durability for carrying groceries and gifts.

Manufacturing uses automated machines to cut, fold, glue, and print bags, with strict quality control to ensure reliability.

Choosing recycled paper bags supports sustainability by reducing plastic waste and lowering environmental impact.

You might wonder, when were paper bags invented? The story begins in the early 1850s. Francis Wolle invented and patented the first machine to mass-produce flat, envelope-style paper bags around 1852. This invention made it possible for you to use paper bags in everyday life. Official records show that James Baldwin received Letters Patent No 2190 on September 22, 1853, for improvements in making paper bags. These early patents confirm the timeline for the invention of paper bags and mark the start of paper bag history.

Several inventors shaped the history of paper bags. Francis Wolle created the original envelope-style bag. Margaret E. Knight changed the industry in 1871 by inventing a machine that made flat-bottomed paper bags. Her design allowed you to carry more items, making shopping easier. Charles Stilwell improved the design in 1883 by adding pleated sides, creating the self-opening sack (SOS) bag. Walter Deubener added handles in 1912, so you could carry up to 20 pounds of groceries. By 1915, over a million handled bags sold each year, showing the commercial success of these innovations.

| Year | Inventor/Developer | Innovation/Benchmark | Numerical Benchmark/Impact |

|---|---|---|---|

| 1852 | Francis Wolle | First machine to mass-produce envelope-style paper bags | Enabled mass production of simple flat bags |

| 1871 | Margaret E. Knight | Machine for flat-bottomed paper bags | Bags could carry more items than envelope style |

| 1883 | Charles Stilwell | Patent for SOS (Self-Opening Sack) paper bag machine | Introduced pleated sides for foldability and storage |

| 1912 | Walter Deubener | Paper bags with handles | Bags could carry up to 20 pounds of food |

| 1915 | Walter & Lydia Deubener | Over a million bags sold per year | Demonstrated commercial success and widespread adoption |

The history of grocery bags shows how packaging changed retail and daily life. Early paper bags had simple shapes and limited strength. As inventors improved designs, you gained bags that could hold more and last longer. The addition of handles made shopping more convenient. Over time, the history of grocery bags reflects bigger changes in packaging. For example:

Since 2015, England’s charge on single-use plastic bags led to a 98% drop in usage.

The sustainable packaging market is growing fast, expected to reach over $423 billion by 2029.

More than 40% of companies plan to use new sustainable packaging by 2025.

You can see that the invention of paper bags and the evolution of grocery bags have shaped how stores and shoppers think about packaging. The history of paper bags connects directly to today’s focus on sustainability and responsible retail practices.

When you ask, "where do paper bags come from," you start with the forests. Most paper bags begin as wood pulp, which comes from trees grown in sustainably managed forests. These forests get replanted and cared for, so you help protect the environment when you choose a paper bag made this way. Some companies also use recycled materials, which means they turn old paper products into new bags. This process saves trees and reduces waste.

You might wonder about the impact of making paper bags. Producing one sheet of paper uses about 10 liters of water. To make one tonne of white paper, you need around 17 trees. The pulp and paper industry uses about 6% of all industrial energy and creates 2% of direct industrial CO2 emissions. These numbers show why it matters to choose sustainable packaging and support recycled kraft paper options. When you pick a bag made from recycled or alternative fibers like bamboo, you help lower the demand for virgin wood and reduce pollution.

Besides wood pulp, manufacturers add other materials to make paper bags stronger and more useful. They use inks for printing logos, glues for sealing seams, and ropes or ribbons for handles. These extra materials help create bags that fit many needs, from groceries to gifts.

Tip: Next time you shop, look for paper bags labeled as made from recycled materials. You make a positive impact with every choice.

You might notice that most paper bags feel sturdy and tough. This strength comes from kraft paper, which is the main material for making these bags. Kraft paper comes from wood pulp, but not all wood works the same. Manufacturers often use softwood trees like pine or spruce because their long fibers give the paper bag extra strength.

The process to make kraft paper starts with selecting the right wood. Workers remove the bark and clean the wood to get rid of impurities. Then, they cook the wood chips with chemicals like caustic soda or sulfate. This step removes lignin, a substance that holds wood fibers together, but keeps the fibers strong. The result is kraft pulp, which makes high-quality, durable paper.

Here’s a table that shows how different choices in the kraft process affect the quality of the paper bag you use:

| Aspect | Details | Impact on Paper Bag Quality |

|---|---|---|

| Wood Type | Softwood (pine, spruce) vs. hardwood (birch, poplar) | Softwood gives longer fibers and more strength |

| Bark Presence | More bark in the mix | Lowers strength and durability |

| Pulping Method | HALT vs. conventional kraft pulping | HALT increases pulp yield and preserves strength |

| Additives | Sizing agents, fillers, waterproofing | Improves water resistance and printability |

| Alternative Materials | Straw, hemp, recycled fibers | Offers sustainable and recycled options |

You also find paper bags made from recycled kraft paper. These bags use fibers from old paper products, which helps save resources and energy. Some manufacturers blend recycled fibers with new pulp to balance strength and sustainability. When you choose a bag made from recycled materials, you support a cleaner environment and help reduce waste.

Note: The source of wood and the pulping method both affect the final quality of your paper bag. Bags made from high-quality kraft paper last longer and carry heavier loads.

If you ever wondered, "where do paper bags come from," now you know that the answer involves careful choices at every step—from the forest to the factory. Your everyday decisions can support recycled, sustainable packaging and help protect the planet.

You might wonder how a simple sheet of paper turns into a sturdy bag you can use every day. The manufacturing process starts with pulping. Workers mix wood chips with water and chemicals to create a pulp. Machines clean and press this pulp into large sheets of paper. Next, these sheets move to cutting machines, which slice them into the right size for each bag.

After cutting, machines fold the paper into shape. Glue seals the edges and bottom, making sure the bag holds together. If the bag needs handles, workers or machines attach ropes or ribbons at this stage. Printing comes next. Companies add logos, designs, or instructions using safe inks. Each step uses careful planning and automation to keep up with demand.

Here’s a table that shows the main steps and supporting elements in the process:

| Step | Supporting Elements |

|---|---|

| Sourcing raw materials | Eco-friendly suppliers, logistics partners |

| Converting to paper | Durable paper production |

| Cutting, folding, gluing | Automated machines, skilled workers |

| Handle attachment | Ropes, ribbons, adhesives |

| Printing | Safe inks, custom designs |

| Quality control | Inspections, compliance checks |

Tip: Automation helps factories make up to 10,000 bags a day, keeping up with the growing demand for sustainable packaging.

You want your bag to be strong and reliable. Quality control teams check every batch to make sure each bag meets high standards. Inspectors test seams, print clarity, and handle strength. They use international standards like ISO 2859-1 to decide how many bags to check and what defects are allowed. For example, they accept no critical defects, only 2.5% major defects, and up to 4% minor defects.

Regular checks help catch problems early. Factories aim for a defect rate below 2% and supplier reliability above 95%. They also reuse over 70% of scrap materials, which saves resources and reduces waste. These efforts lead to a 15% increase in positive customer feedback and help the environment by cutting plastic waste by at least 30%.

Note: Careful quality control means you get a bag that is safe, strong, and ready for daily use.

You see many types of paper bags in stores, each with its own features and uses. The right grocery bag design helps you carry food, clothes, or gifts safely and easily. Let’s look at the most common types of paper bags you might use.

Flat-bottom bags are the most popular grocery bag design. You find them in supermarkets, bakeries, and takeout restaurants. These bags have a simple rectangular base, which makes them easy to fill and stack. The flat bottomed paper bag stands upright on its own, so you can pack items quickly. Most of these bags use brown kraft paper, which is strong and eco-friendly.

Lightweight and economical

Easy to recycle and customize with logos

Perfect for groceries, baked goods, and retail items

Tip: Flat-bottom bags dominate the market because they balance cost, strength, and sustainability. You help the environment every time you choose one.

Here’s a quick comparison of flat-bottom bags with other styles:

| Specification Category | Flat-Bottom Paper Bags | Other Styles (SOS, Euro totes, etc.) |

|---|---|---|

| Shape | Rectangular | Square, circular, or specialty |

| Capacity | 1 KG – 5 KG | Varies by use |

| Handles | Twisted, flat, or none | Fancy, ziplock, or hand length |

| Market Position | Most widely used | Niche or premium uses |

S.O.S. (Self-Opening Sack) bags are another common grocery bag design. You often see them in convenience stores and fast-food outlets. These bags have side gussets that let them expand, so you can fit more items inside. The S.O.S. bag opens easily with one hand, which makes it great for busy shoppers.

Side gussets for extra space

Stand upright when filled

Used for snacks, sandwiches, and small groceries

S.O.S. bags show how grocery bag design can make shopping faster and more convenient.

Handled bags give you extra comfort when carrying heavier loads. You see this grocery bag design in clothing stores, gift shops, and takeout restaurants. Handles can be twisted paper, flat paper, or even rope. This feature makes it easy to carry up to 20 pounds of goods.

Strong handles for easy carrying

Popular for retail, food service, and gifts

Often used for branding and promotions

You find many types of paper bags in the market. Each type fits a different need, from daily groceries to special gifts. The right grocery bag design helps you shop smarter and supports a cleaner planet.

You see paper shopping bags everywhere in your daily life. Grocery stores use brown paper grocery bags to pack food and drinks. Retail shops choose paper shopping bags to give you a sturdy and attractive way to carry clothes, books, or gifts. In the food industry, bakeries and cafes rely on paper grocery bags to keep snacks and baked goods fresh. Chemical companies use special valve bags to prevent spills and contamination. Farmers and agricultural businesses pack grains and fertilizers in strong, recycled paper bags. E-commerce companies select present-day paper bags for shipping because they protect products and support eco-friendly features.

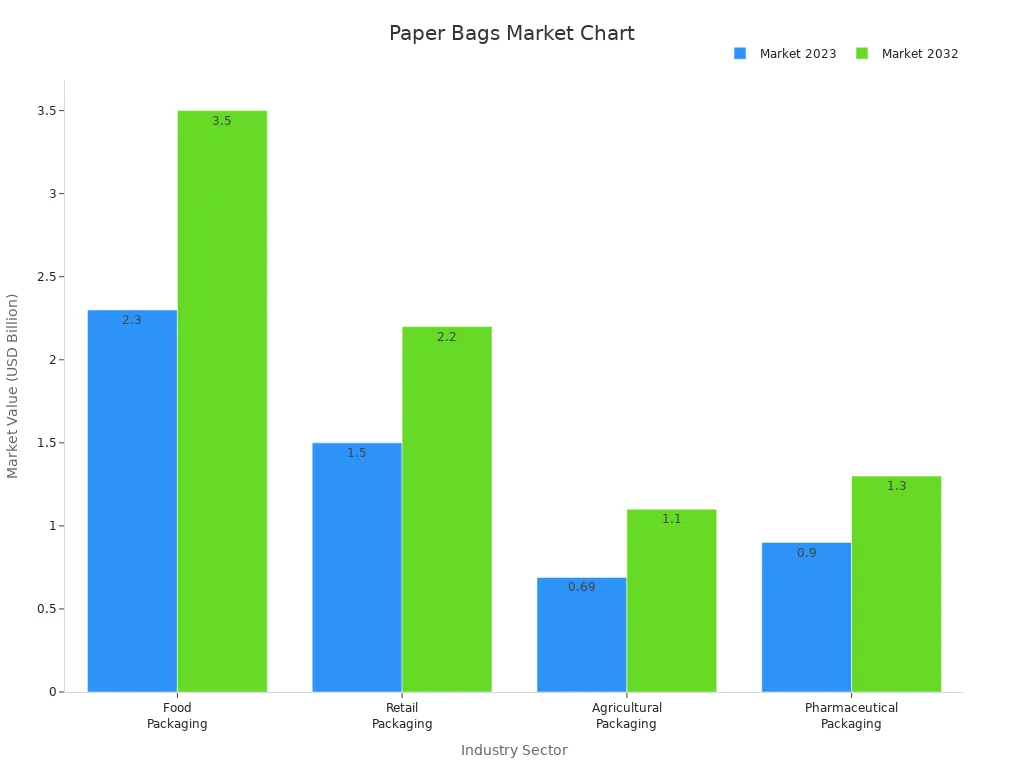

The North America Paper Bags Market report shows that food, agriculture, and retail sectors all prefer paper shopping bags for their cost-effectiveness and recyclability. You help the environment when you choose recycled or present-day paper bags. The demand for these bags keeps growing as more companies adopt environmentally friendly practices.

| Industry Sector | Market Value 2023 (USD Billion) | Projected Market Value 2032 (USD Billion) | Key Drivers and Notes |

|---|---|---|---|

| Food Packaging | 2.3 | 3.5 | Strong demand for sustainable packaging aligned with consumer preference for eco-friendly products. |

| Retail Packaging | 1.5 | 2.2 | Growth driven by brands adopting paper bags to enhance eco-friendly image. |

| Agricultural Packaging | 0.69 | 1.1 | Emphasis on safe and sustainable packaging solutions in agriculture. |

| Pharmaceutical Packaging | 0.9 | 1.3 | Important for product safety and regulatory compliance. |

Life-cycle assessments show that paper shopping bags have a lower environmental impact than many alternatives, especially when you recycle them.

You find many companies competing in the paper shopping bags market. Leading brands like Mondi Plc, Smurfit Kappa Group, International Paper Company, and Novolex Holdings focus on innovation and sustainability. These companies launch new products, form partnerships, and expand into new regions. Asia Pacific leads the market, holding over 30% of the revenue share. The global market is expected to reach $8.4 billion by 2032, growing steadily each year. Most businesses prefer medium-priced paper shopping bags, and B2B sales channels dominate the market. You benefit from this competition because it drives better quality, more recycled options, and new eco-friendly features.

You often choose between paper shopping bags and plastic bags. Paper bags come from renewable resources and break down naturally. Plastic bags, however, can last hundreds of years and cause microplastic pollution. Studies show that paper bags use more water and energy during production, but plastic bags create more long-term waste. Recycling rates for paper bags are much higher than for plastic. When you reuse or recycle paper shopping bags, you help reduce landfill waste and support environmentally friendly practices. Returnable and reusable packaging, like present-day paper bags, can cut greenhouse gas emissions by up to 86% compared to single-use plastic bags.

Tip: Choose recycled paper shopping bags whenever possible. You make a positive difference for the planet.

You have seen how paper bags started with Francis Wolle’s invention in 1852 and grew into a symbol of eco-friendly living. Margaret Knight’s flat-bottom design made shopping easier. Today, you use paper bags every day for groceries, gifts, and more. Their biodegradable and recyclable nature supports a cleaner planet.

| Aspect | Evidence Summary |

|---|---|

| Market Size & Growth | Global paper bags market valued at $6.0 billion in 2024; projected to reach $8.6 billion by 2033. |

| Environmental Benefits | Paper bags are biodegradable, recyclable, and made from renewable resources. |

| Consumer Trends | More people choose eco-friendly packaging and move away from plastics. |

Choosing paper bags helps you support sustainability and a healthier environment. Every bag you use makes a difference.

You usually find kraft paper made from wood pulp in most paper bags. Some bags use recycled paper fibers. Manufacturers may add inks, glues, or handles made from rope or ribbon.

Yes, you can recycle most paper bags in your curbside recycling bin. Remove any non-paper handles or decorations first. Clean, dry bags recycle best.

Paper bags can carry heavy items, especially those with reinforced handles. You may notice that paper bags hold up well for groceries and gifts. Plastic bags stretch more but do not break down as easily.

You use paper bags in many places. Retail shops, bakeries, restaurants, and even pharmacies rely on them. Farmers and e-commerce companies also use paper bags for packaging and shipping.